Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: XGJ560

Jenama: YULONG

Pembungkusan: Sesuai untuk pengangkutan laut atau pengangkutan udara

Produktiviti: 1.5-2t/h

Pengangkutan: Ocean,Air

Tempat asal: Shandong, China

Sokongan mengenai: 500 sets per year

Sijil: CE,ISO, SGS

Kod HS: 84793000

Port: Qingdao

Jenis bayaran: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

XGJ siri mesin cecair biomass mangga mesin yang berkesan telah mengguna pakai intipati kilang pelet di pasaran luar negeri. Bahagian jantung "double layer die" mempunyai pemasangan struktur yang unik dan "penggelek" dibuat bahan aloi yang mudah pakai tinggi. Kedua-dua bahagian ini mempunyai watak-watak: reka bentuk tertentu, struktur yang munasabah, tenaga yang rendah, kecekapan yang tinggi, angkat panjang dan sebagainya. Melalui banyak pakar teknikal yang bekerja keras, syarikat kami telah membangunkan produk paten khas ini yang muncul pertama di pasaran domestik. Mesin baru telah memenuhi negara kosong dalam pemakanan menegak untuk kilang pelet mati cincin dan mencapai tahap maju antarabangsa.

Yulong Brand biomass mango wood pellet press machine advantages

|

1 |

Double-layer stainless steel ring die, up and down side. One ring die can be using 2 times by turn it over. Reduce operating costs. |

|

2 |

Vertical ring die, feeding vertically, the raw materials can follow to the pellet machine pelleting room directly. |

|

3 |

Vertical ring die structure, easy for heating dissipation, which can keep the machine running continually. |

|

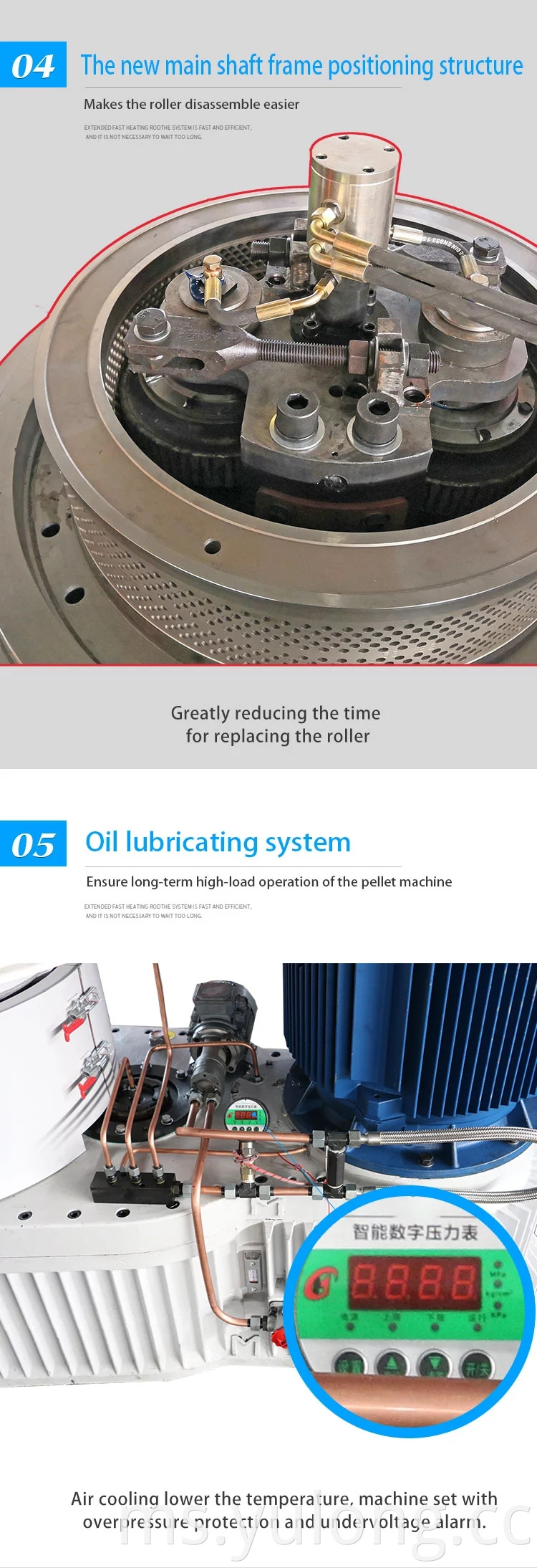

4 |

Ring die fixed, main shaft vertically, main shaft and roller rotating , the roller only can rotating inside of the ring die, so no deflection, no shaking, machine running more stably. |

|

5 |

Vertical ring die fixed, roller rotating, with centrifugal force, making the materials evenly distributed around inside the die, also the centrifugal force will help improve the capacity. |

|

6 |

Extremely compact kick-out device, more stable during working. |

|

7 |

The cover of kick-out device adopt 304 stainless steel, anti-wear and corrosion -resistant. |

|

8 |

The cover of kick-out device to be pressed one time forming, high strength. |

|

9 |

Two sets lubrication system--one is lubrication pump to lubricate rollers, the other is lubrication pipe to lubrication main shaft and gear box which ensure the pellet machine can work long time. |

|

10 |

Thin oil lubrication cooled by air, and equipped with overpressure protection and underpressure alarm, real-time display of circulating pressure, to ensure long-term high load operation of pellet mill. |

|

11 |

The position of pellet outlet and kick-out reducer can be adjusted according to customers` wishes or factory field situation. |

|

12 |

The main shaft adopt high stiffness load-bearing structure, diameter increased 15%. And the load-bearing surface of main shaft bearing added 1 time. More stable operation and lower failure rate, aimed to make the pellet machine output higher. |

|

13 |

The new positioning structure of main shaft supporting frame makes it easier to disassemble the roller and greatly reduces the time for users to replace the roller. |

|

14 |

The new pressure roller surface adopts the technology of the robot surfacing alloy which extend the service lifetime of the roller. |

|

15 |

The mould all used high-end wear-resistant stainless steel plus advanced vacuum furnace quenching technology, hardness of surface and inside is the same. |

|

16 |

The mould hole is machined by ultra-high speed gun drill, and the it can be used after grinding slightly. |

Yulong menegak cincin die biomass mangga kayu mesin pelet tekan Spesifikasi:

|

Model |

Power(kw) |

Capacity(ton/h) |

Weight(ton) |

Dimension(mm) |

|

XGJ560(5th) |

90 |

1-1.5 |

5.3 |

2600*1300*2300 |

|

XGJ850(5th) |

220 |

2-3 |

14.5 |

3300*1400*3100 |

|

XGJ560(7th) |

132 |

1.5-2 |

4.5 |

2588*1250*1602 |

|

XGJ850(7th) |

250 |

3-4 |

13.5 |

2650*1850*2100 |

YULONG jentera pembuatan

Pusat pemilihan YULONG

Syarikat YULONG

Mesin Yulong menguatkan sistem penghantaran

1. struktur ketumpatan: penghantaran dengan aci selari tiga gigi keras perlahan, peningkatan modulus gear, pelebaran gear, pengukuhan, kekuatan penghantaran adalah 3-5 kali pengurangan konvensional.

2.Power input: penggunaan motor penjimatan tenaga yang cekap, pasang sambungan secara langsung, tinggi koaksial, aci berkelajuan tinggi dengan struktur aci sejajar, aci gear adalah dua pusingan sokongan, ketegaran yang tinggi, transmisi lancar dan boleh dipercayai, untuk meninggalkan kuasa yang lebih besar .

3. Output kuasa: output deice dan spindle menjadi satu, untuk meninggalkan bentuk sambungan terhad, kekuatan meningkat 2-3 kali.

4. Menguatkan batang aci: panjang aci dipendekkan, kekakuan yang bertambah baik dengan ketara, kekakuan tinggi aci dapat mengurangkan haus acuan dan penggelek.

5. Pemasangan fleksibel: cawangan peranti boleh menjadi putaran berbilang sudut, pemasangan peralatan yang lebih fleksibel dan pelbagai.

Proses pembuatan mesin Yulong :

Kategori produk : Mesin pelet > Mesin Pelet Kayu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.